Descripción del producto:

El inyector de flujo rotativo modelo HDR-2133 es un producto de vanguardia diseñado para la industria del aluminio, que ofrece capacidades avanzadas de refinación y desgasificación.Con un intervalo de tiempo de refinación y desgasificación de 0 a 99 minutos, este inyector garantiza un rendimiento y una eficiencia óptimos en el proceso de producción de aluminio.

Diseñado en una sorprendente combinación de colores azul y amarillo, el inyector de flujo rotativo HDR-2133 no solo destaca visualmente sino que también significa su alta calidad de construcción y atención al detalle.Con un peso aproximado de 3500 kg, este inyector es resistente y duradero, construido para soportar los rigores del uso industrial.

Como parte de su dirección de desarrollo hacia la digitalización y la inteligencia, el inyector de flujo rotativo HDR-2133 está a la vanguardia de la innovación en la industria del aluminio.Está equipado con tecnología de última generación para mejorar la eficiencia y la productividad., para satisfacer las necesidades cambiantes de la industria.

Una de las características clave del inyector de flujo rotativo HDR-2133 es su compatibilidad con una amplia gama de piezas de inyector, incluyendo boquilla de inyector Isuzu, piezas de inyector Cummins,y partes de inyectores BOSCHEsta flexibilidad permite un fácil mantenimiento y personalización, garantizando una integración perfecta con los sistemas existentes.

Ya sea que desee actualizar su actual instalación de producción de aluminio o que busque una solución fiable para sus necesidades de refinación y desgasificación,el inyector de flujo rotativo HDR-2133 es una opción versátil y eficienteSu diseño innovador y su enfoque en la digitalización lo convierten en una inversión a prueba de futuro para las empresas de la industria del aluminio.

Características:

- Nombre del producto: inyector de flujo rotativo

- Peso: alrededor de 3500 kg

- Mecanismo de suministro de agentes de refinación: rotativo

- Material del tanque del agente de refinación: 316L

- Velocidad del rotor de grafito: 0 ‰ 400 r/min

- Categoría de producto: inyector de flujo rotativo

Parámetros técnicos:

| Instrucciones |

Tratamiento de purificación de fundición, proceso clave de refinación en horno, dispositivo avanzado de purificación de horno |

| Peso |

Alrededor de 3500 kg |

| Potencia total del equipo |

≤ 20 kW |

| Velocidad del rotor de grafito |

0 ¥ 400 r/min |

| Material del tanque del agente de refinación |

Las demás: |

| Ventajas |

Burbujas distribuidas en todo el fundido, refinación de alta eficiencia, efecto de purificación del aire |

| Categoría de productos |

Inyector de flujo giratorio |

| Modelo |

HDR-2133 |

| Marca del producto |

Haydeb |

| El color |

Azul y amarillo |

Aplicaciones:

Oportunidades y escenarios de aplicación del producto para el inyector de flujo giratorio HYDEB XCP230-1:

El inyector de flujo rotativo HYDEB XCP230-1 es un producto de vanguardia diseñado para la eliminación de hidrógeno, deslagging, refinación y desgasificación en el procesamiento de aluminio líquido.Con sus características y capacidades avanzadas, este producto es ideal para diversas ocasiones y escenarios de aplicación en la industria del aluminio.

Nombre de marca: HYDEB

Número de modelo: XCP230-1

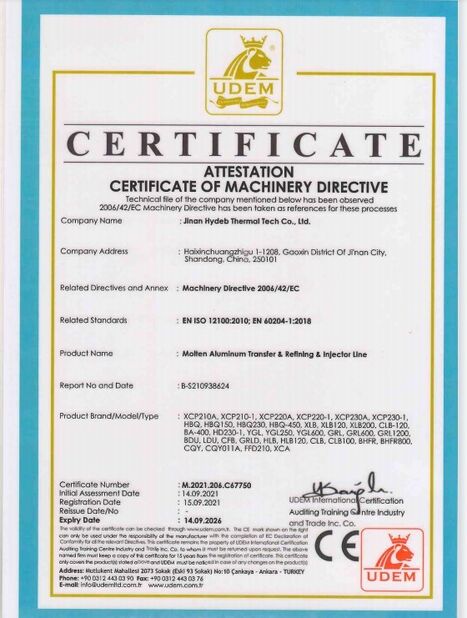

Certificación: certificado CE, ISO

Lugar de origen: China.

Cantidad mínima de pedido: 1 conjunto

Precio: $15000-$30000 por juego

Términos de pago: por T/T

Capacidad de suministro: 1000 unidades/año

Tiempo de entrega: 2 meses

Detalles del embalaje: Caja de madera

El inyector de flujo rotativo HYDEB XCP230-1 es adecuado para las siguientes ocasiones de aplicación:

1. Plantas de fundición de aluminio: El producto se puede utilizar en plantas de fundición de aluminio para procesos eficientes de eliminación de hidrógeno, deslagging y refinación.

2. Fundiciones e instalaciones de fundición: es ideal para su uso en fundiciones e instalaciones de fundición para mejorar la calidad del aluminio líquido mediante desgasificación y purificación del aire.

3Centros de reciclaje de aluminio: El inyector de flujo rotativo se puede utilizar en los centros de reciclaje de aluminio para mejorar la purificación y refinación de materiales de aluminio reciclados.

4Talleres de fabricación de metales: se puede integrar en talleres de fabricación de metales para la refinación y desgasificación precisas del aluminio líquido utilizado en varios procesos de fabricación.

Dirección de desarrollo: Digitalización e inteligencia, I+D de nuevos equipos para soluciones industriales de ALU

Velocidad del rotor de grafito: 0 ‰ 400 r/min

Tiempo de refinación y desgasificación: 0 ¢ 99 min

Ventajas: Burbujas distribuidas en toda la fusión, alta eficiencia de refinación, efecto de purificación del aire

En general, el inyector de flujo rotativo HYDEB XCP230-1 ofrece piezas de inyector de Chuck Rotary Attachment, Cummins Injector Parts y BOSCH Injector Parts.Este producto es un activo valioso para mejorar las operaciones de procesamiento de aluminio en diferentes industrias..

Apoyo y servicios:

El equipo de soporte técnico del producto Rotary Flux Injector se dedica a ayudar a los clientes con cualquier problema relacionado con el producto.Nuestro personal experto está disponible para proporcionar orientación sobre la instalación, solución de problemas y mantenimiento para garantizar un rendimiento óptimo.

Además del soporte técnico, ofrecemos diversos servicios para mejorar la experiencia del cliente.y actualizaciones de productos para mantener su inyector de flujo rotativo funcionando de la mejor manera.

Embalaje y envío:

Nombre del producto: inyector de flujo rotativo

Descripción: El inyector de flujo rotativo es un dispositivo de vanguardia diseñado para inyectar flujo de manera eficiente en maquinaria rotativa para un rendimiento óptimo.

Incluye: inyector de flujo rotativo, manual de instrucciones

Información de envío: Este producto será cuidadosamente empaquetado y enviado a su dirección en un plazo de 3-5 días hábiles.

Preguntas frecuentes:

P: ¿Cuál es la marca del inyector de flujo rotativo?

R: La marca es HYDEB.

P: ¿Cuál es el número de modelo del inyector de flujo rotativo?

R: El número de modelo es XCP230-1.

P: ¿Dónde se fabrica el inyector de flujo rotativo?

R: El inyector de flujo rotativo se fabrica en Shandong, China.

P: ¿Cuál es la cantidad mínima de pedido para el inyector de flujo rotativo?

R: La cantidad mínima de pedido es 1 SET.

P: ¿Cuáles son las condiciones de pago aceptadas para la compra del inyector de flujo rotativo?

R: El pago se acepta por T/T.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!