Rotor de grafito personalizado para calentamiento y rendimiento a alta temperatura

Descripción del producto:

Con un tiempo de garantía de 1 mes, los clientes pueden estar tranquilos sabiendo que están cubiertos en caso de cualquier problema o defecto imprevisto. La fuente de alimentación eléctrica del producto garantiza un rendimiento eficiente y constante, lo que lo hace adecuado para una variedad de aplicaciones.

El control de calidad es una prioridad para este producto, con una inspección del 100% realizada antes del envío para garantizar que cada pieza cumpla con los más altos estándares de excelencia. Esta meticulosa atención al detalle garantiza que los clientes reciban solo piezas de repuesto de fundición a presión de la mejor calidad.

Las piezas de repuesto de fundición a presión están disponibles en un color blanco clásico, lo que agrega una apariencia limpia y profesional a cualquier maquinaria o equipo en el que se utilicen. Esta opción de color versátil facilita la integración de las piezas de repuesto en los sistemas existentes.

Los componentes clave de las piezas de repuesto de fundición a presión incluyen el eje de grafito, el rotor de grafito y el eje de grafito, que son conocidos por su durabilidad, resistencia y confiabilidad. Estos componentes juegan un papel crucial en el rendimiento y la funcionalidad general de las piezas de repuesto, lo que los hace esenciales para un funcionamiento óptimo.

En general, el producto de piezas de repuesto de fundición a presión es una solución confiable y de alta calidad para las empresas que necesitan piezas de repuesto duraderas y eficientes. Su aplicación versátil, fuente de alimentación eléctrica, estrictas medidas de control de calidad, color blanco clásico y componentes clave como el eje de grafito y el rotor de grafito lo convierten en una opción superior para diversas industrias.

Aplicaciones:

Las piezas de repuesto de fundición a presión Hydeb son componentes versátiles adecuados para una amplia gama de ocasiones y escenarios de aplicación de productos. Con un nombre de marca sinónimo de calidad y confiabilidad, las piezas de repuesto Hydeb están diseñadas para cumplir con los más altos estándares de la industria.

El número de modelo Hydeb garantiza una fácil identificación y compatibilidad, lo que lo convierte en una opción conveniente para varios proyectos. Originarias de China, estas piezas de repuesto vienen con la garantía de una artesanía superior e ingeniería de precisión.

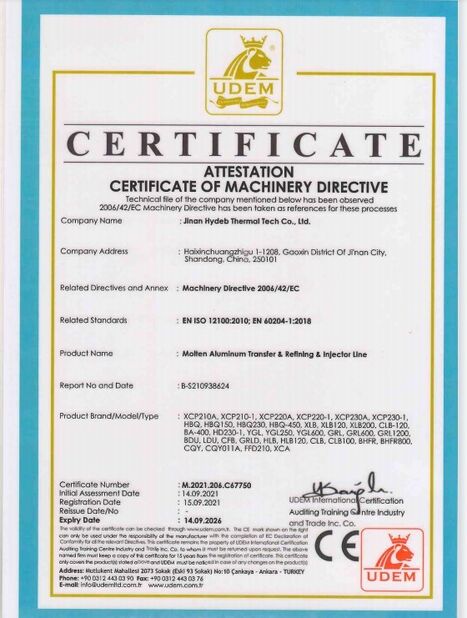

Las piezas de repuesto Hydeb están certificadas con ISO CE, lo que garantiza el cumplimiento de los estándares internacionales de calidad y seguridad. La cantidad mínima de pedido de 1 permite flexibilidad en la adquisición, mientras que el precio competitivo de 150 USD lo convierte en una solución rentable para empresas de todos los tamaños.

Empaquetadas en cajas de madera para un tránsito seguro, el tiempo de entrega de 50 a 60 días garantiza la recepción oportuna de los pedidos. Las condiciones de pago del 30% + 70% ofrecen comodidad y flexibilidad financiera a los clientes.

Con una capacidad de suministro adaptada para satisfacer los requisitos específicos del pedido, las piezas de repuesto de fundición a presión Hydeb funcionan con electricidad, lo que garantiza un funcionamiento eficiente y un rendimiento constante. La vida útil del molde de 50.000 a 100.000 disparos destaca la durabilidad y longevidad de estas piezas de repuesto.

Utilizando un proceso antioxidante, el material del molde de H13, SKD61, etc., garantiza la resistencia a la corrosión y al desgaste, lo que hace que las piezas de repuesto Hydeb sean ideales para un uso a largo plazo. La dureza de 80-100 HB mejora aún más la robustez y la resistencia de estos componentes.

Ya sea que se utilicen en maquinaria industrial, aplicaciones automotrices o electrónica de consumo, las piezas de repuesto de fundición a presión Hydeb sobresalen en varios escenarios. Su confiabilidad y alto rendimiento las convierten en una opción indispensable para las empresas que buscan componentes de eje de grafito de primera calidad.

Embalaje y envío:

Embalaje del producto:

Nuestras piezas de repuesto de fundición a presión se empaquetan cuidadosamente para garantizar que lleguen de forma segura a su puerta. Cada pieza se envuelve en material protector y se coloca en una caja resistente para mayor seguridad durante el transporte.

Envío:

Ofrecemos servicios de envío confiables para garantizar que sus piezas de repuesto de fundición a presión le lleguen de manera oportuna. Dependiendo de su ubicación, utilizamos transportistas de confianza para entregar su pedido de forma segura y eficiente. Puede rastrear su envío y recibir actualizaciones sobre el estado de la entrega para su tranquilidad.

Preguntas frecuentes:

P: ¿Cuál es el nombre de la marca de las piezas de repuesto de fundición a presión?

R: El nombre de la marca es Hydeb.

P: ¿Dónde se fabrican las piezas de repuesto de fundición a presión?

R: Las piezas se fabrican en China.

P: ¿Cuál es la certificación de las piezas de repuesto de fundición a presión?

R: Las piezas están certificadas ISO CE.

P: ¿Cuál es la cantidad mínima de pedido para las piezas de repuesto de fundición a presión?

R: La cantidad mínima de pedido es 1.

P: ¿Cuáles son los detalles del embalaje de las piezas de repuesto de fundición a presión?

R: Las piezas se empaquetan en cajas de madera.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!